The flow velocity is measured by collecting a volume of the fluid (V) over a time period (t). The conservation of energy or the Bernoulli’s equation can be expressed as: This probe is inserted into the duct with its end-hole facing the flow so that the flow becomes stagnant locally at this end thus: The total head (h t) may be measured by the traversing hypodermic probe. In which is called the velocity head (h d). Therefore, Bernoulli’s equation for the test section can be written as: The pressure head (h), thus, is calculated as: The hydrostatic pressure (P) along the flow is measured by manometers tapped into the duct. In this experiment, since the duct is horizontal, the difference in height can be disregarded, i.e., z 1=z 2 These two laws and the definition of work and pressure are the basis for Bernoulli’s theorem and can be expressed as follows for any two points located on the same streamline in the flow: Thus, the input mass and energy for a given control volume are equal to the output mass and energy: These assumptions are also based on the laws of conservation of mass and energy. Theoryīernoulli’s theorem assumes that the flow is frictionless, steady, and incompressible.

Figure 2.2: Test sections, manometer positions, and diameters of the duct along the test section 7. The flow through the test section can be adjusted by the apparatus control valve or the bench control valve. The pressure tappings are connected to manometers that are mounted on a baseboard. To prevent damage, the probe should be fully inserted during transport/storage. This probe may be moved after slackening the gland nut, which should be re-tightened by hand. A probe is provided to measure the total pressure head along the test section by positioning it at any section of the duct. The test section incorporates two unions, one at either end, to facilitate reversal for convergent or divergent testing. The dimensions of the test section, the tapping positions, and the test section diameters are shown in Figure 2.2. Manometers allow the simultaneous measurement of the pressure heads at all of the six sections along the duct. Figure 2.1: Armfield F1-15 Bernoulli’s apparatus test equipment

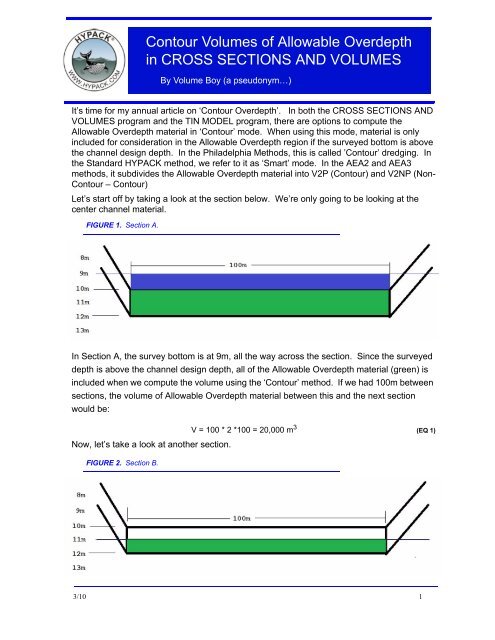

#Hypack beach volume cross sections series

Series of side hole pressure tappings are provided to connect manometers to the test section (Figure 2.1). The test section is a circular duct of varying diameter with a 14° inclined angle on one side and a 21° inclined angle on other side. The Bernoulli test apparatus consists of a tapered duct (venturi), a series of manometers tapped into the venturi to measure the pressure head, and a hypodermic probe that can be traversed along the center of the test section to measure the total head.

It has many real-world applications, ranging from understanding the aerodynamics of an airplane calculating wind load on buildings designing water supply and sewer networks measuring flow using devices such as weirs, Parshall flumes, and venturimeters and estimating seepage through soil, etc. Practical Applicationīernoulli’s theorem provides a mathematical means to understanding the mechanics of fluids. The validity of Bernoulli’s equation will be examined in this experiment. Bernoulli’s theorem pertaining to a flow streamline is based on three assumptions: steady flow, incompressible fluid, and no losses from the fluid friction. The relationship among these three forms of energy was first stated by Daniel Bernoulli (1700-1782), based upon the conservation of energy principle.

IntroductionĮnergy presents in the form of pressure, velocity, and elevation in fluids with no energy exchange due to viscous dissipation, heat transfer, or shaft work (pump or some other device). Experiment #2: Bernoulli’s Theorem Demonstration 1.

0 kommentar(er)

0 kommentar(er)